How scientists are transforming plastic waste into food-safe ingredients

I don’t think I need to explain to you that we have a plastic problem.

But, if you’re a numbers person, we produce 359 million tons of plastic every year, and 150–200 million of those tons end up in landfills. That’s over 40%.

Not great.

I’m curious, though — how do you feel about converting plastic into food ingredients? Would you eat the upcycled food?

And this isn’t just some imaginary solution.

The seemingly impossible transformation of plastic waste into food-safe ingredients has recently been proven feasible in a study that converted water bottles into vanillin, aka artificial vanilla flavoring.

Breaking down plastic

The main issue with recycling plastics is that when they’re melted down and reformed, the new material doesn’t behave the same way as virgin plastic.

This is why making new plastic is easier than recycling what we already have.

So, the question becomes, is there anything else we can do with plastic besides make more plastic?

One idea is to take the plastic polymer, a large molecule made up of repeating subunits, and hydrolyze it back into these smaller subunits.

The idea is that the smaller compounds might be more useful than the polymer itself.

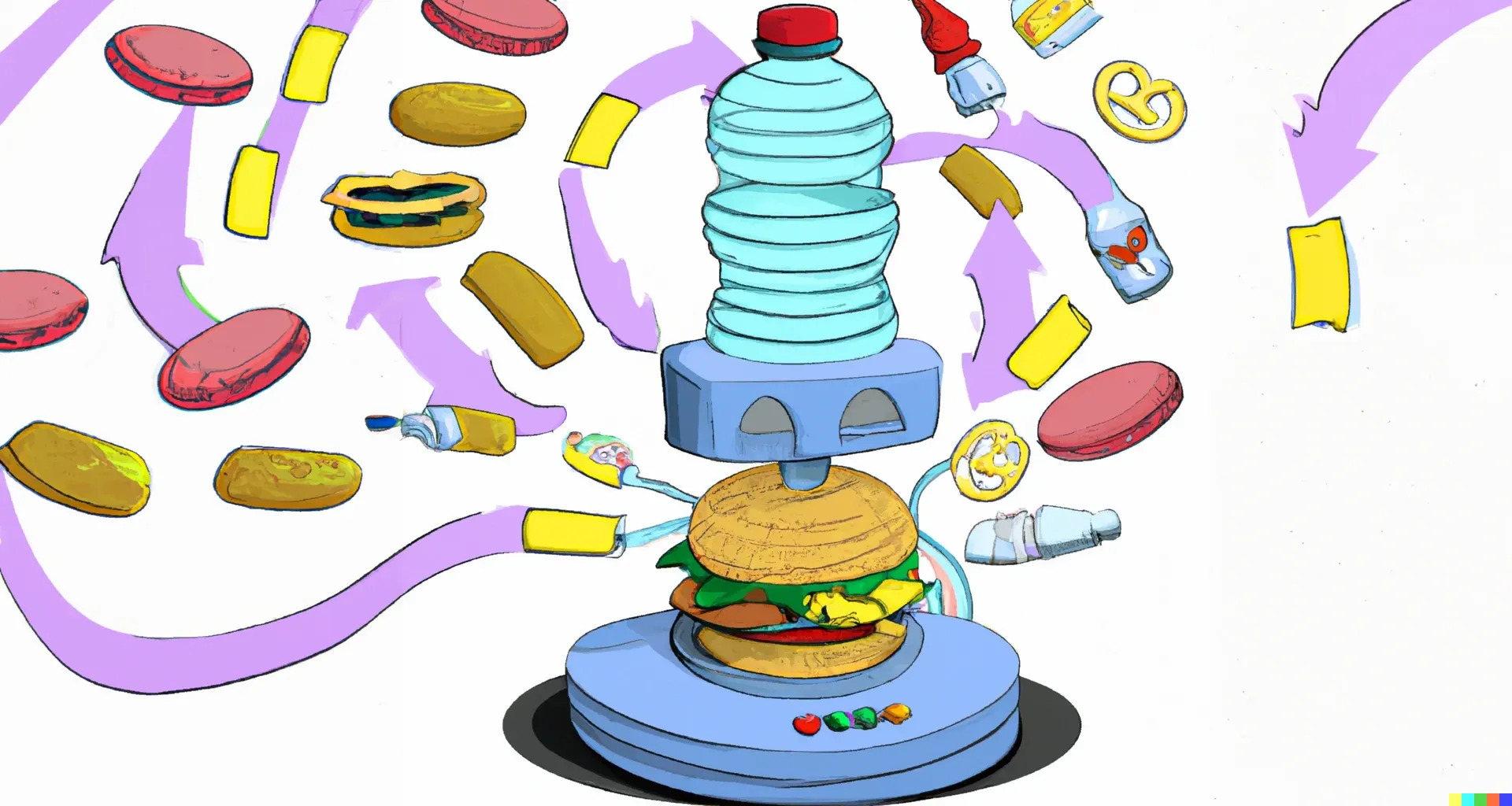

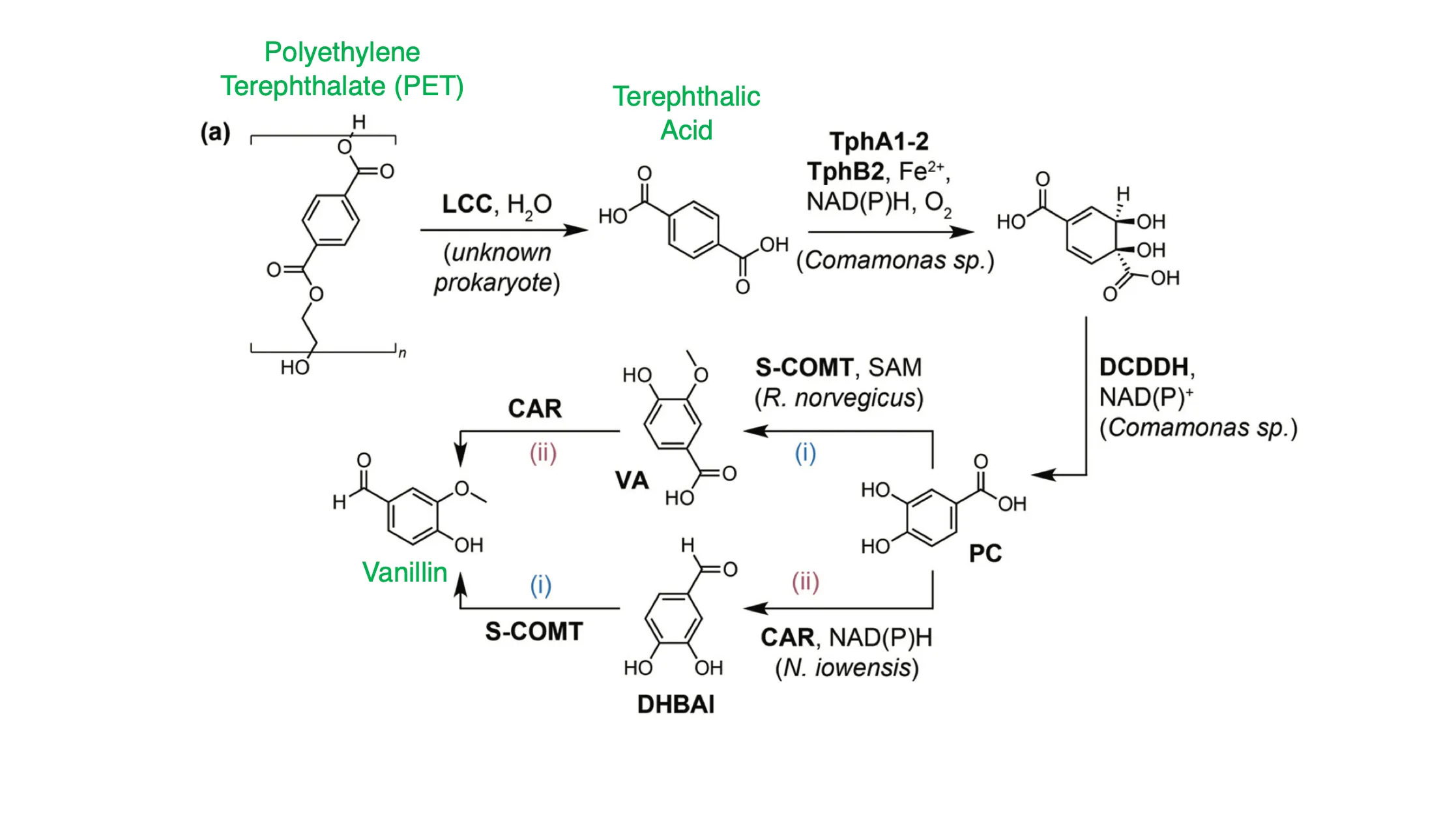

Hydrolysis of Polyethylene Terephthalate (PET) yields units of Terephthalic Acid (TA). Image taken from Microbial synthesis of vanillin from waste poly(ethylene terephthalate) by Sadler and Wallace.

For example, polyethylene terephthalate (PET), which is used to make water and soda bottles, can be cut up into smaller molecules of terephthalic acid and ethylene glycol. Perhaps it would be easier to convert these two smaller compounds into a new, more valuable material.

Up until two years ago, the main issue with this solution was that there was no efficient enzyme for chopping up plastics like PET. And it wasn’t for lack of trying.

Scientists have tested multiple enzymes known for hydrolyzing PET but with little success.

The most efficient enzyme found — Leaf-branch Compost Cutinase — which was originally isolated from the bacteria Ideonella sakaiensis only converted 31% of PET into its smaller subunits.

That all changed in 2020 when one group of researchers made 209 different variations of Leaf-branch Compost Cutinase by selectively mutating the area that interacts with PET. This area is called the active site and is where an enzyme comes in contact with its substrate.

The researchers laboriously tested all 209 variations to see how they interacted with the plastic from water and soda bottles.

While most of the altered enzymes had an impaired ability to cut up PET, one version showed great promise with a 90% efficiency of converting PET into its smaller units of terephthalic acid and ethylene glycol.

This was a massive success!

The group went on to show that when the smaller subunits were used to re-create PET, the plastic polymer behaved just like virgin PET, creating a circular plastic system.

If this system was upscaled, no more virgin PET would have to be made. We could simply use all the PET we currently have to produce the same plastic again and again.

Making it edible

While recycling the PET into second-hand PET is a step in the right direction, another group of scientists had an even bigger dream. They wanted to upcycle the two subunits of PET — terephthalic acid and ethylene glycol — to make something more valuable.

Not simply keep the PET in a never-ending plastic loop.

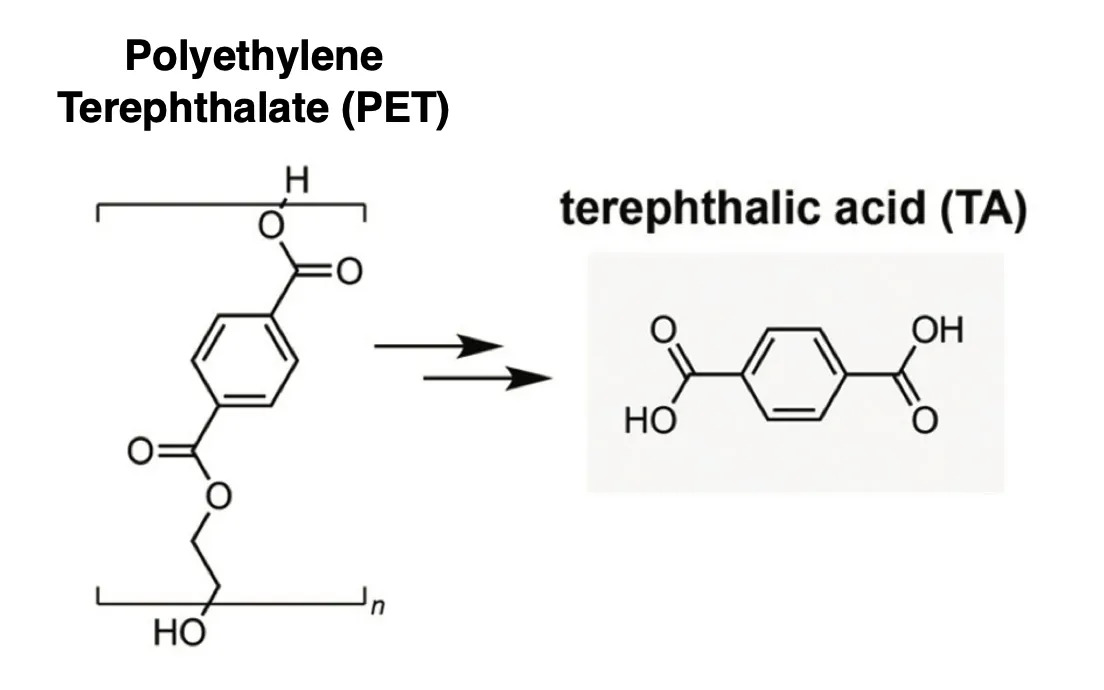

The researchers noticed something interesting about the terephthalic acid units — they looked quite similar to vanillin — the main flavor compound in vanilla.

Chemical structure of terephthalic acid versus vanillin. Image taken from Microbial synthesis of vanillin from waste poly(ethylene terephthalate) by Sadler and Wallace.

The group drew out a plan and estimated it would only takefive steps to convert terephthalic acid to vanillin.

A five-step plan to convert Terephthalic acid into vanillin. Image taken from Microbial synthesis of vanillin from waste poly(ethylene terephthalate) by Sadler and Wallace.

While every step in the plan was feasibly possible, some of the reactions required specific enzymes found in different organisms. To circumvent this issue, the team decided to engineer their own microorganism that contained all the enzymes needed for the upcycling.

To do this, they took the bacteria Escherichia coli — better known as E. coli — and inserted three new plasmids, giving the species all the necessary enzymes to synthesize vanillin from terephthalic acid.

The scientists then used the terephthalic acid units from plastic water bottles as feed for the engineered bacteria and waited to see if the culture produced the vanillin as hoped.

After 10 hours, 79% of the terephthalic acid was transformed into vanillin.

A big success and proof that flavor compounds could be produced from plastics by combining the hydrolysis of PET by Leaf-branch Compost Cutinase with metabolism by the newly engineered E. coli.

Would you eat food made from plastic?

Even though the vanillin synthesized from plastic is chemically identical to the artificial vanilla flavoring sold in stores AND the vanillin in vanilla beans, I’m guessing there’s going to be a good amount of skepticism.

And I get it; something about eating food made from plastic water bottles seems unsettling (although I’m incredibly curious).

Not to mention, the enzymes and bacteria that aid in the process have been genetically altered, which always draws some criticism.

On the other hand, it’s an interesting way to deal with the massive amounts of plastic pollution we’ve created. Not to mention, the upcycled vanillin could be a huge price savings for consumers especially compared to natural vanilla flavoring that’s been extracted from the fickle vanilla orchid.

Don’t even get me started on how tedious working with vanilla orchids is — I’ve already written a detailed article about it.

One fun fact though — most vanilla flowers have to be HAND pollinated, one by one, using a little Q-tip. Getting those vanilla beans is extremely labor-intensive, so I hope you better appreciate them.

If eating upcycled food doesn’t become the norm, there are still other options for the upcycled vanillin.

It could be used for non-edible products like perfumes and fragrances. I mean, how many personal care products, from shampoo to deodorants, offer vanilla scents? Not to mention air fresheners! I mean, would people really object to upcycled vanilla covering up their stink?

Perhaps time will tell because the upcycling process has only been successful on a lab scale and still needs to be greatly upscaled to have any impact on our plastic crisis.

But I will say, before finding this study, I never considered that a solution to plastic pollution would be converting it into food ingredients.

I thought the idea was incredibly innovative and creative, albeit a little out there.