From cultured meat to ice cream, here’s what you can expect from lab-grown foods

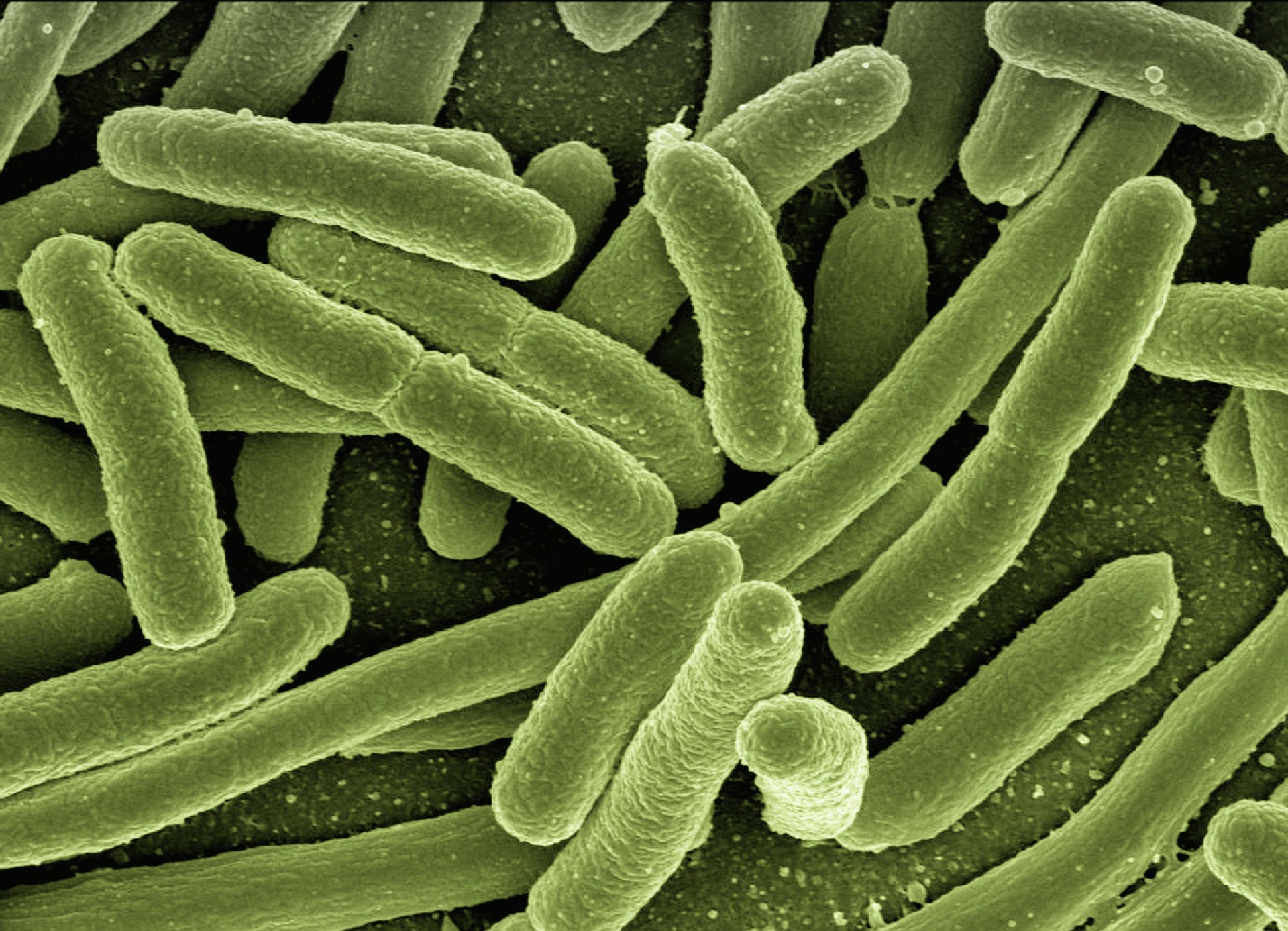

The transformation from farm-to-table into lab-to-table has already begun, with many startups delving into cellular agriculture. This entails growing foods in large bioreactors that utilize specialized microorganisms to generate food or quite literally growing food cell by cell.

Within the next few decades, farming and agriculture as we know it could be entirely upended, morphing from a sector that heavily relied on land and animals into an industry that could be contained within a laboratory.

While there currently aren’t any cell-based meats available in the supermarket, one startup, Memphis Meats, recently announced a Series B funding round of $161 million.

“We are providing compelling and delicious choices by producing real meat from animal cells, its natural building blocks,” Memphis Meats co-founder and CEO Uma Valeti said in a January statement.”Cell-based meat is poised to dramatically expand humanity’s capacity to feed a growing population while preserving our culinary traditions and protecting our planet.”

Would you eat a steak that wasn’t from a real cow?

Amid unpredictability surrounding health, animal well-being, and climate change, the one thing that seems inevitable is the need for a food system that increasingly incorporates technology and limits waste.

But what will that look like on the plate? Here’s a sampling of products that will be among the first to test the viability of the lab-to-table pipeline.

Animal-free meat

I’m not talking about Impossible Burgers here — nothing about this is plant-based. Producing cultured meat is the process of growing muscle cells outside of the animal’s body. You still need an animal to start — say, a cow — to harvest stem cells from. This can be done using anesthesia on live animals during a biopsy.

In animals, these cells would multiply in response to stress or injury to regrow muscle tissue. The same process is used to make cultured meat — except it’s carried out in a lab.

The stem cells are transferred into a broth that’s rich in nutrients like amino acids and sugars. The cells will continue to proliferate over time amid the abundant nutrients. This means the original stem cells harvested from an animal can be used to make trillions and trillions of more cells.

When enough stem cells have been generated, the differentiation stage can begin. Here, the culture conditions are slightly altered to coax the stem cells to differentiate into skeletal muscle cells. Mosa Meat claims they simply stop giving the cells certain growth factors and they’ll differentiate on their own.

After differentiation, the muscle cells are transferred onto a scaffold that encourages them to form into strips. This is key to matching the texture of animal meat, which has a fibrous structure to it.

Once the cells have combined to create long fibers, the meat is almost ready to be sold. Then the product can be shaped into patties, seasoned, packaged, and shipped.

Although no products are currently on the market, Memphis Meats and Mosa Meat aim to break into the cultured meat game. In 2013, Mosa Meat’s co-founder, Mark Post, introduced the first cultured burger, which cost a staggering $282,000 to produce.

Memphis Meats, meanwhile, plans to use the Series B funding haul to construct a pilot manufacturing facility with the goal of bringing its products to market in 2021. Memphis Meats ultimately aims to create beef, chicken, and duck products, but no launch date has been announced. Even with an extensive amount of funding and research, it seems it’ll be at least a year or two before we’ll see these products on supermarket shelves.

Protein from ‘thin air’

Made by Solar Foods, Solein is a protein powder with a flour-like consistency that boasts “it’s literally born out of thin air.” That’s a bit of an exaggeration, although the process only requires hydrogen, carbon dioxide, and Solar Food’s proprietary yeast.

Solein is made through a fermentation process that uses carbon-capture technology to extract carbon dioxide from the air and generates hydrogen by sending an electric current through water, both of which are key nutrients used to feed the yeast. Some of the hydrogen produced also reacts with nitrogen from the air to yield ammonia, which provides nitrogen to the tiny organisms.

The food sources and yeast are collected into large vats, and a couple of vitamins and minerals are added. The yeast cells chow down on the hydrogen bubbles and carbon dioxide, yielding a single-cell protein called Solein.

Unbelievable? I’m a food scientist, and I don’t think it’s too far-fetched to exploit microorganisms to produce our food. Consider that we already use specialized microbes to produce insulin and vitamin supplements — several vitamins like D, B6, and B12 are now made exclusively from microbial fermentation. It’s a logical extension of these technologies to expand into the food sector.

Once the Solein is separated from the yeast and dried, it closely resembles wheat flour in taste and appearance. According to Solar Foods, the nutritional breakdown is over 50 percent protein, 20–25 percent carbohydrates, and 5–10 percent fat.

With its neutral taste and color, Solein could, in theory, be substituted into nearly any food product as a sustainable protein source. The company expects it to be used in everything from pasta and bread to yogurt and beverages. Solar Foods plans to begin commercial production in 2021.

Frozen treats from yeast

Cows and ice cream are inextricably linked. But food technology company Perfect Day aims to change that: It created a specialized group of yeast that can generate dairy proteins identical to those produced by cows. Of course, microorganisms don’t naturally make dairy proteins, so the flora was engineered using recombinant technology.

Simply put: A small pieces of genetic material from a cow that encoded how to make dairy proteins was inserted in the yeasts’ own genetic sequence. Due to the universality of DNA, the tiny organisms could then read the cow’s genetic material as if it were the instructions for making proteins.

There’s a term for swapping DNA from one species into another: genetically modified. Although the yeast are genetically modified organisms (GMOs), the protein they produce doesn’t contain the modified DNA. This means it won’t have to be labeled as a bioengineered food under current regulation.

When the yeast — or, as Perfect Day likes to call it, “microflora” — is fed sugar, it produces the two main proteins in milk: whey and casein. Then, the proteins have to be filtered out from the living cells and dried into a powder. The yeast-made proteins are chemically identical to those made by cows and are equivalent in texture, taste, and nutrition.

I mean identical: For allergy purposes, the label on Perfect Day’s ice cream must say it “contains milk.” Except it… doesn’t leading to confusion over how it will be labeled.

Perfect Day first debuted its “flora-based dairy protein” last July in three flavor variations of ice cream: vanilla salted fudge, milky chocolate, and vanilla blackberry toffee. But the launch was limited: Perfect Day only promised 1,000 orders. But despite a sticker price of $20 per pint, the ice cream sold out within hours of being released.

Consumers that got a taste of Perfect Day’s cow-free frozen treats flocked to the internet to tell those of us still in the dark how microflora-based ice cream stacks up. Most reviews described a creamy, smooth products nearly identical to regular ice cream.

Perfect Day ultimately aims to expand into all types of dairy products, including milk, cheese, and yogurt. But it’s hush-hush about when our next chance to taste the microflora-based proteins will be, with no launch dates released since the ice cream debuted.

Lab-grown breast milk

There’s about to be a newcomer to the old breastfeeding-versus-formula debate — cultured breast milk. Turtle Trees Labs and Biomilq are both exploring new technologies to collect milk from living, lactating cells.

Turtle Tree Labs uses animal mammary gland cells that live in a nutrient broth to secrete milk. They then filter the milk out from the rest of the solution. Biomilq claims to have a cleaner process that uses human mammary gland cells that secrete milk, which can be directly collected.

Both companies aim to create a better alternative to current formulas, which are either based on cows’ milk or composed of soy protein. These substitutes for breast milk lack the protective components of mother’s milk like antibodies that fight disease, white blood cells to combat infection, beneficial bacteria, and enzymes that help with digestion.

And that’s where Biomilq plans to step in with its cultured breast milk, which recently tested positive for two principal components of breast milk — human casein and lactose. Although further molecular tests are needed to detail other components, Biomilq believes it’s on the way to matching the thousands of nutritional and protective components found in mother’s milk.

Ultimately, the success of food produced by cellular agriculture all comes down to consumer acceptance. So, now that you have a sense of how these foods are made, here’s a question: Would you eat a steak that wasn’t from a real cow?